Aluminium-Verarbeitungswerk

Schwingungsüberwachungssystem für Kaltwalzwerke und Streckrichtmaschinen

Die Herausforderung

Qualität ist im Aluminiumverarbeitungsgeschäft zweifellos Geld. Als also ein Prozess kritische Schwingungen verursachte, war dies ein großes Problem für eine der führenden Aluminium-Verarbeitungsanlagen im Nahen Osten.

Das iba-System bietet ein hochmodernes Zustands- und Schwingungsüberwachungssystem. Seit dieses System installiert wurde, konnten viele kritische Ausfallzeiten vermieden werden.

Vorteile

Korrelieren von Schwingungsdaten und Maschinendaten

mit nur einem Datenerfassungssystem

Einfache Integration

in ein bestehendes Condition Monitoring-Programm

Vermeidung

kritischer Ausfallzeiten

Die Lösung

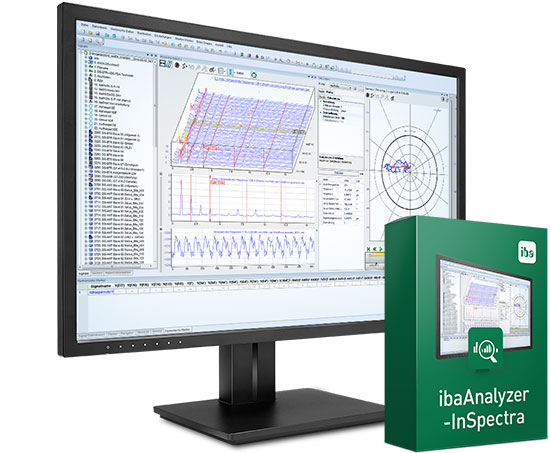

Bei der kritischen Bewertung einer verfahrenstechnischen Anlage sind Prozessdaten nicht wegzudenken. In diesem Fall erfolgt die Datenerfassung mit einem ibaPDA-System, während die Prozessanalyse auf den gesammelten Daten mit dem ibaAnalyzer durchgeführt wird.

Die Schwingungsüberwachung wird jedoch auf verteilten Edge-Geräten durchgeführt. Nach der Erfassung der Schwingungsdaten von Beschleunigungsaufnehmern wird das ibaPDA-Add-On ibaInSpectra verwendet, um diese Daten zu analysieren. ibaInSpectra arbeitet mit einer Frequenzbandanalyse. Damit werden Maschinen-, Prozess- und Produktdaten genutzt, um schwingungsbedingte Qualitätsprobleme der Anlage zu eliminieren.

Omer Akhtar

System Engineer,

iba Gulf

iba-Produkte

Die wichtigsten Eigenschaften der verwendeten Komponenten