Acoustical monitoring in the engine testing technology

Acoustics testing with ibaInSpectra

Test benches at an automobile engine plant had to be retrofitted by the test bench manufacturer to include acoustics analysis. Before including an iba system, long-term tests (> 300 h.) had to be interrupted at night, as employees only work for two shifts.

To optimize testing efficiency, the test bench manufacturer decided to implement a reliable monitoring system that automatically shuts down the test bench when vibration and noise level exceed pre-defined thresholds. In the end, the manufacturer decided on the iba system because it can be configured easily and flexibly.

Business Benefits

Uninterruptible

long-term tests

Easy integration

into existing test bench automation

Convenient solution

for acquiring, displaying, and analyzing time and frequency domain data

The Technology

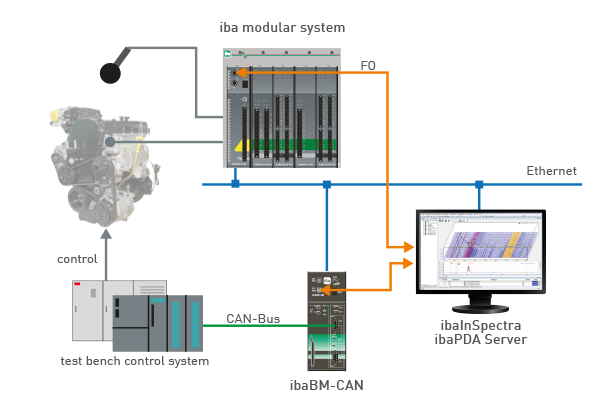

Our ibaPDA (Process Data Acquisition) system can communicate with almost all automation platforms for data collection. At the same time, ibaPADU (Parallel AnalogDigital Unit) can be used to acquire fast analog and digital signals via high-quality analog-digital converters. Due to our broad connectivity and with an acquisition rate of up to 100 kHz, ibaPDA can analyze and hence optimize the behavior of complex and fast processes. With the ibaInSpectra software add-on, iba offers a convenient solution for real-time analysis and visualization of spectral components in machines.

Data recorded on the test bench are made available to experts for time domain and frequency domain analysis using ibaAnalyzer.

The iba system allows for a defined and reproducible measurement procedure that is nevertheless individually adapted to different circumstances and can be extended for further demands.

iba Products