Checking and certifying coil tracking automatically

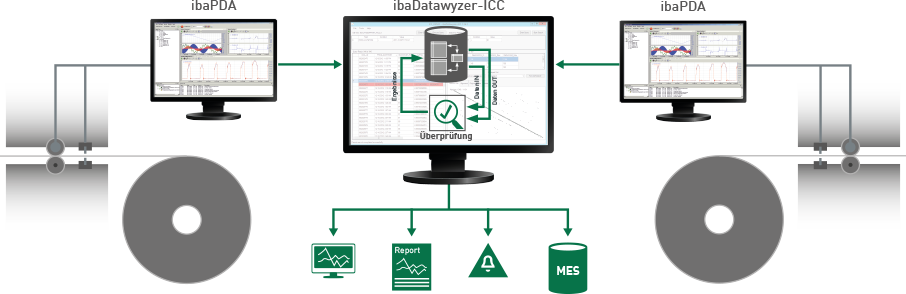

Handling flat products in an optimized way with ibaDatawyzer-ICC

Business Benefits

Coil identification

based on measurement data

Automatic online-monitoring

of the production

Easy integration

in the existing iba

"Based on the geometric properties such as thickness and width, we can uniquely identify a coil and thus exclude confounders."

Detlef Maaß

Product Manager,

iba AG

|Quality Documentation

Back