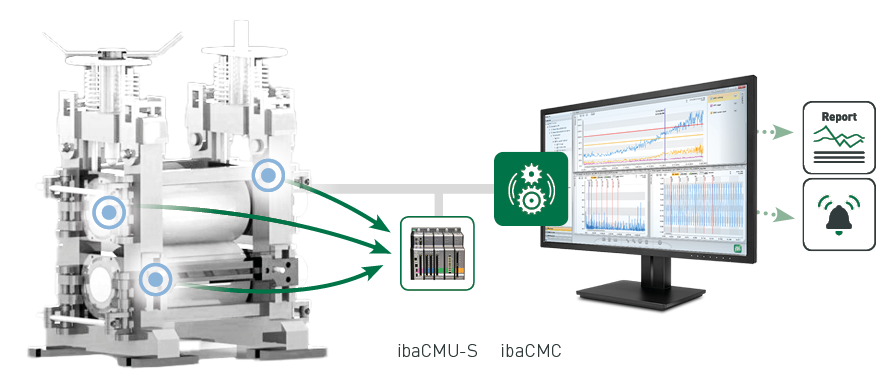

Monitoring gears the intelligent way

Preventing plant downtimes with Condition Monitoring as early warning system

Business Benefits

Minimize

downtimes of production plants

Automatic alarm

when limit values are exceeded

Easy integration

in existing iba systems

"Only with the simultaneous monitoring of all machine, process, material and quality data, the damages on machine parts in complex production plants can be detected reliably."

Christian Gmeinwieser

Application & Consulting,

iba AG

|Condition Monitoring

Back