Undisturbed operation due to voltage monitoring

Power Quality as an important quality feature

In steel works and metallurgical plants, downtime and repair costs due to the power quality disturbances become an increasing challenge. Continuous monitoring of the power quality together with the process data forms the basis for undisturbed operation and the detection of possible failure causes at an early stage. Continuous monitoring of the power network parameters together with the process data forms the basis for faultless operation and the detection of possible failure.

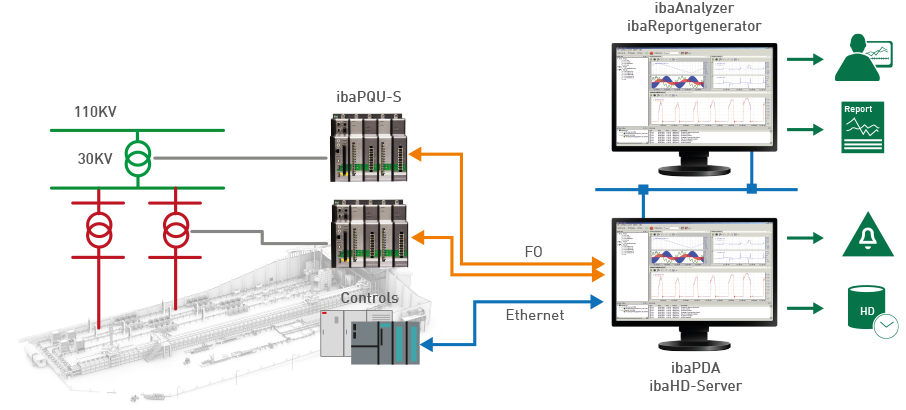

For this reason, a leading steel producer monitors, among other things, the power quality parameters at several transformer stations (from 110KV to 30KV) in order to demonstrate compliance with contractually defined limit values according to IEC50160 standard. In addition, power flows and system perturbations are systematically recorded to optimize the workload of the transformers. In addition, process states from the automation systems were used for the evaluation.

Business Benefits

Line-synchronous

and gapless recording

Simultaneous

acquisition of energy and process data

Standard conformity

according to IEC61000-4-30 Class A (ed.3)

The Technology

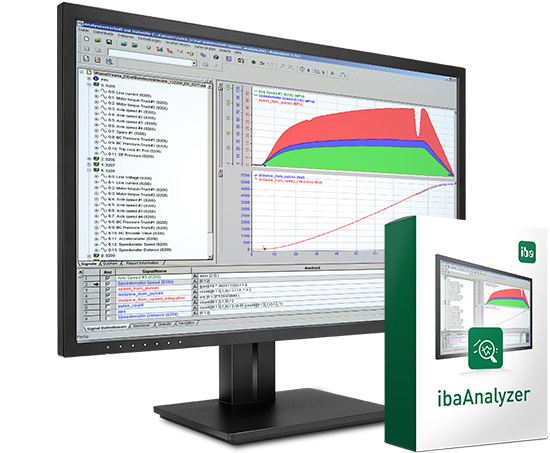

Due to the measurement with ibaPQU-S and further analysis of the measured values with ibaAnalyzer, excessive values of the individual harmonics were detected as well as unbalanced phase load. These parameters could be reduced by optimizing the workload of existing transformers and lines. Since then, the grid has been permanently monitored, which allows an early intervention in the network dynamics.

By combining them with data from PLCs, you are able to react quickly to changes in process chain. Thus, the required product quality is guaranteed and high downtime and repair costs as a result of poor network quality could be reduced.

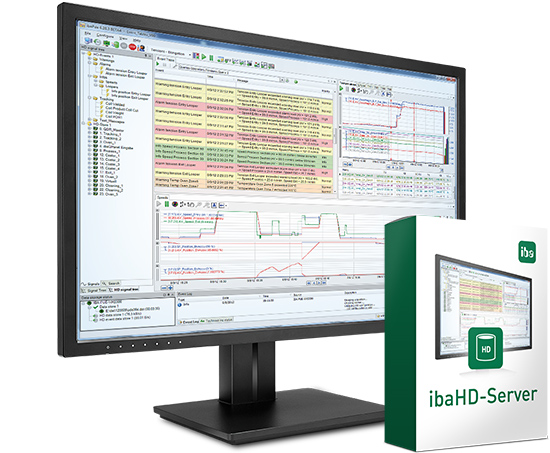

A weekly report with appropriate certification information is generated for the documentation backup.

Thomas Caramagno

PQ Expert,

iba AG

iba Products

Power quality monitoring and fault analysis in a steel mill