Aluminium Processing Plant

Vibration Monitoring System for Cold Rolling Mills and Tension Leveler

The Challenge

Quality certainly equals money in the Aluminium processing business. So, when a strip rolling mill was experiencing critical vibrations, it was a major issue for a leading aluminium processing plant in the Middle East.

The iba system provides a state-of-the-art condition and vibration monitoring system. Since it had been installed, many critical downtimes have been avoided.

Business Benefits

Correlating vibration data and machine data

by using one data acquisition system only

Easy integration

into an existing Condition Monitoring System

Avoiding

critical downtimes

The Solution

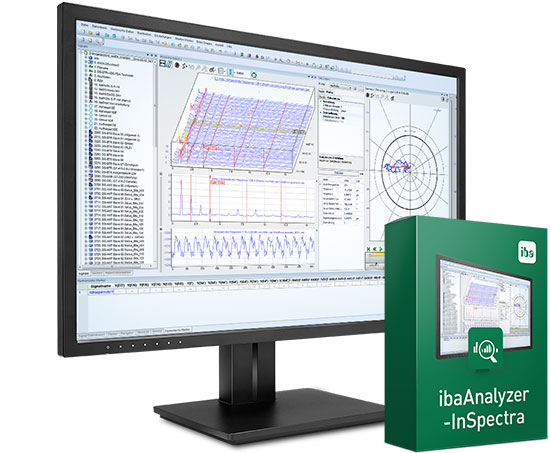

Process data cannot be excluded when doing a critical evaluation fo any process plant. In this case the data recording is performed by a ibaPDA System while the process analysis is performed on collected data with the ibaAnalyzer.

The vibration monitoring however is performed on distributed edge devices. After acquiring the vibration data from accelerometers, the ibaPDA add-on ibaInSpectra is used to analyze this data. The ibaInSpectra utilizes a frequency band analysis. Consequently machine, process and product data is used to eliminate quality problems related to vibration of the system.

Omer Akhtar

System Engineer,

iba Gulf

iba Products

Key features of the used components