ibaQDR 概览

- 质量数据记录系统,基于 ibaPDA 架构

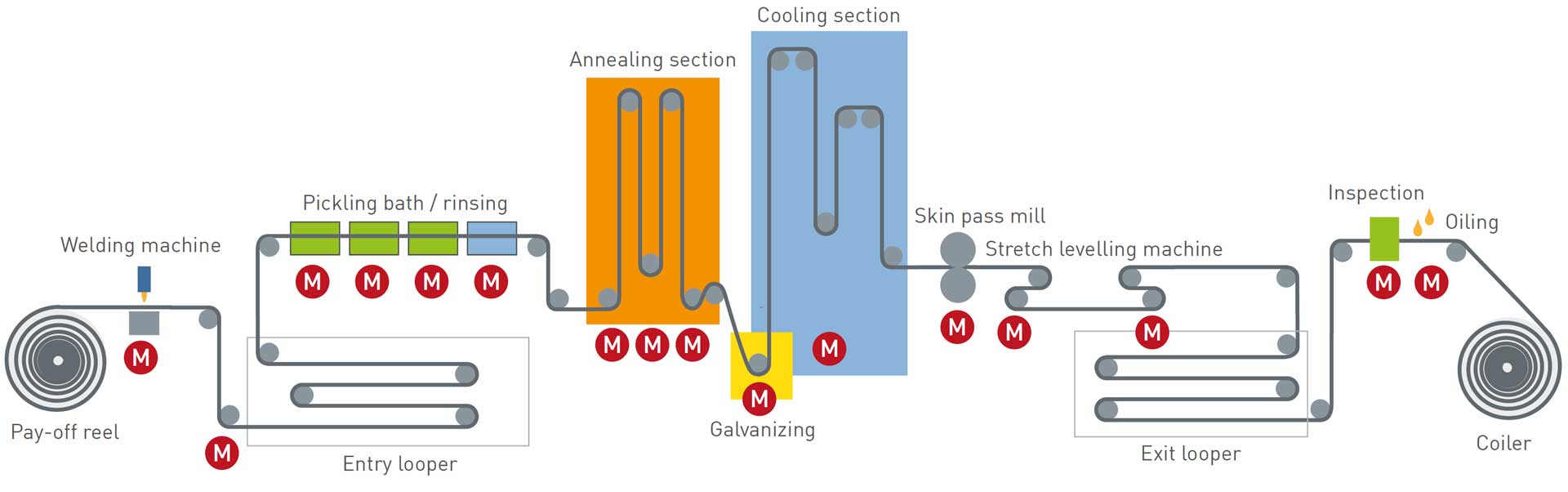

- 带钢加工生产线的工艺过程描述

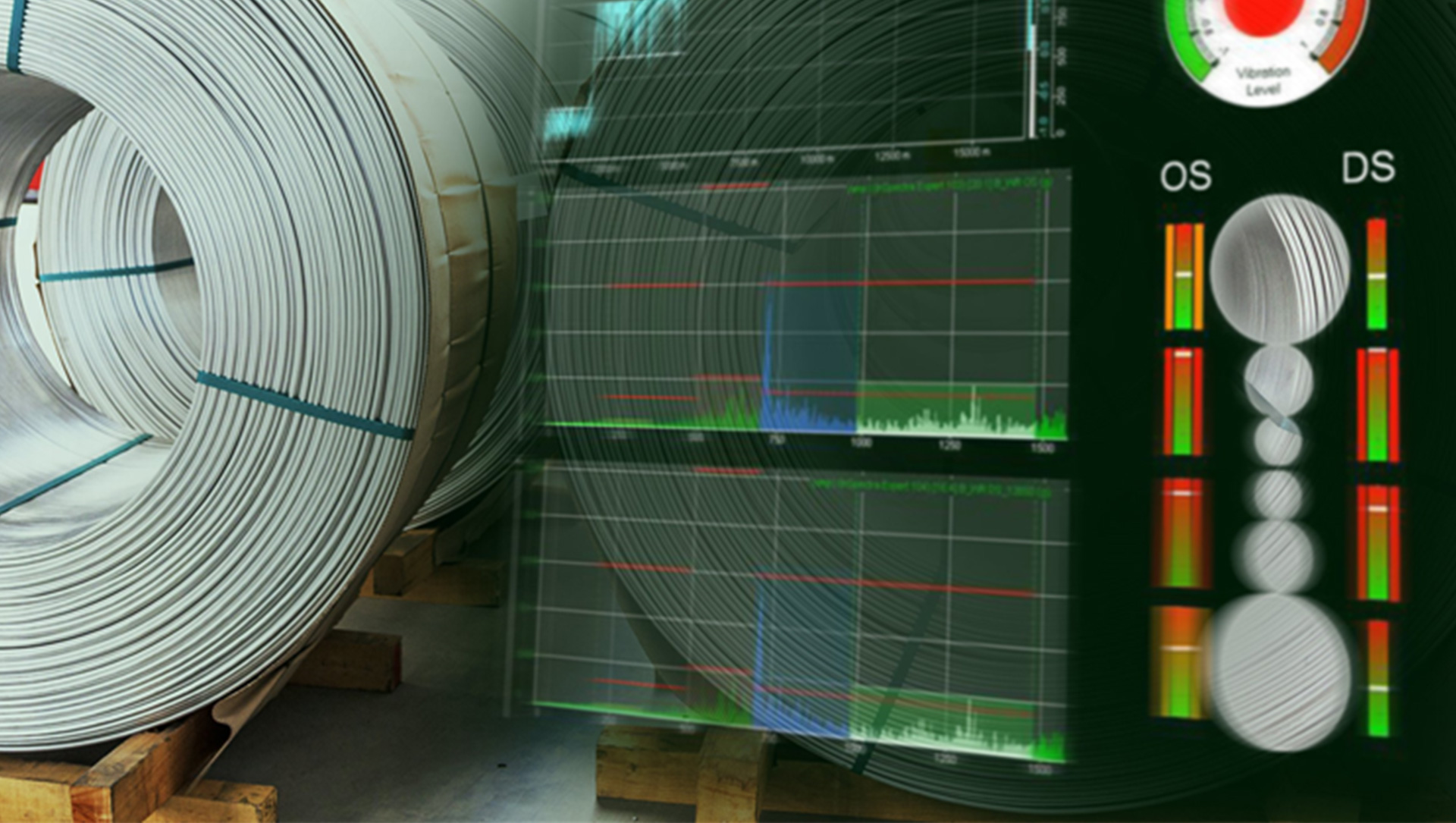

- 对最终产品(钢卷出口Exit coil)进行长度规范化并同步所有测量数据

- 在过程和所有剪切中考虑带钢延伸率

- 标准长度分辨率:1 m(完全可调节,包括单位)

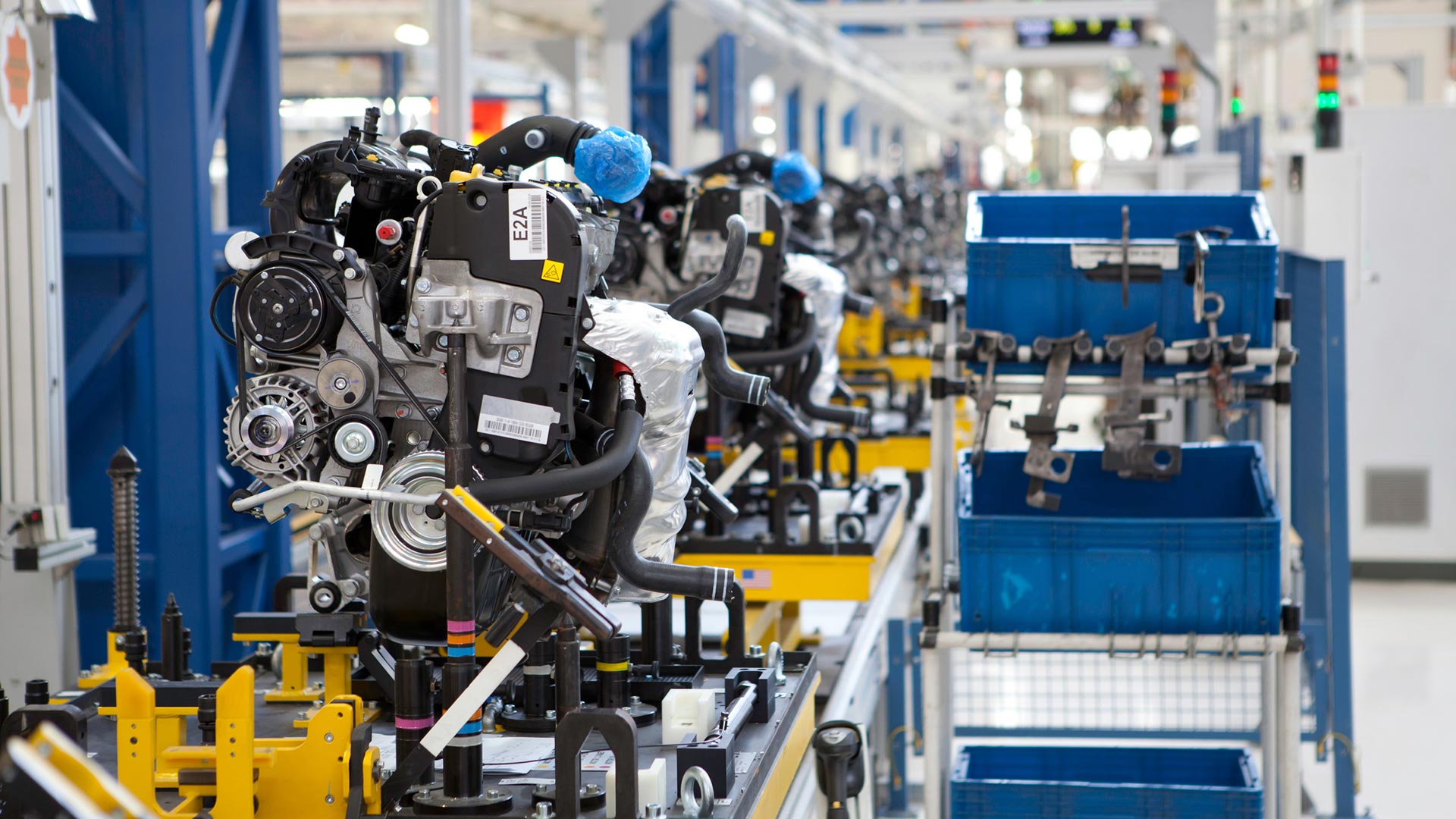

Quality data acquisition of today, is an essential part of the production process for every manufacturer of high-quality products

The quality data recording system ibaQDR is smoothly integrated in ibaPDA as an add-on. The user has the same look-and-feel like in ibaPDA. This offers a transparent quality data acquisition and an efficient data management.

A product (coil)-related analysis of quality data only makes sense, if the relevant measured values can be mapped exactly to the product. In case of long products, a length-based mapping of the data over the product is usually required, e. g. feet-wise or meter-wise.

ibaQDR does this mapping based on the previous time-based recorded data in combination with accurate data of the material tracking. The successively recorded (time-based) data are mapped exactly to the product at the point where they have been measured.

The system has been optimized for rolling mills, processing lines and inspection plants within the metal industry but it can also be used for reversing rolling processes in hot rolling mills or other processes.

Quality relevant data are:

Product dimensions (width, thickness,...)

Cross profiles (strip coating, thickness cross-profile,...)

Production parameters (rolling forces, tensions, ...)

Reference values and consumption figures etc.

ibaQDR generates an exit coil related file, in which the data are mapped exactly to the length.

Functional Principle

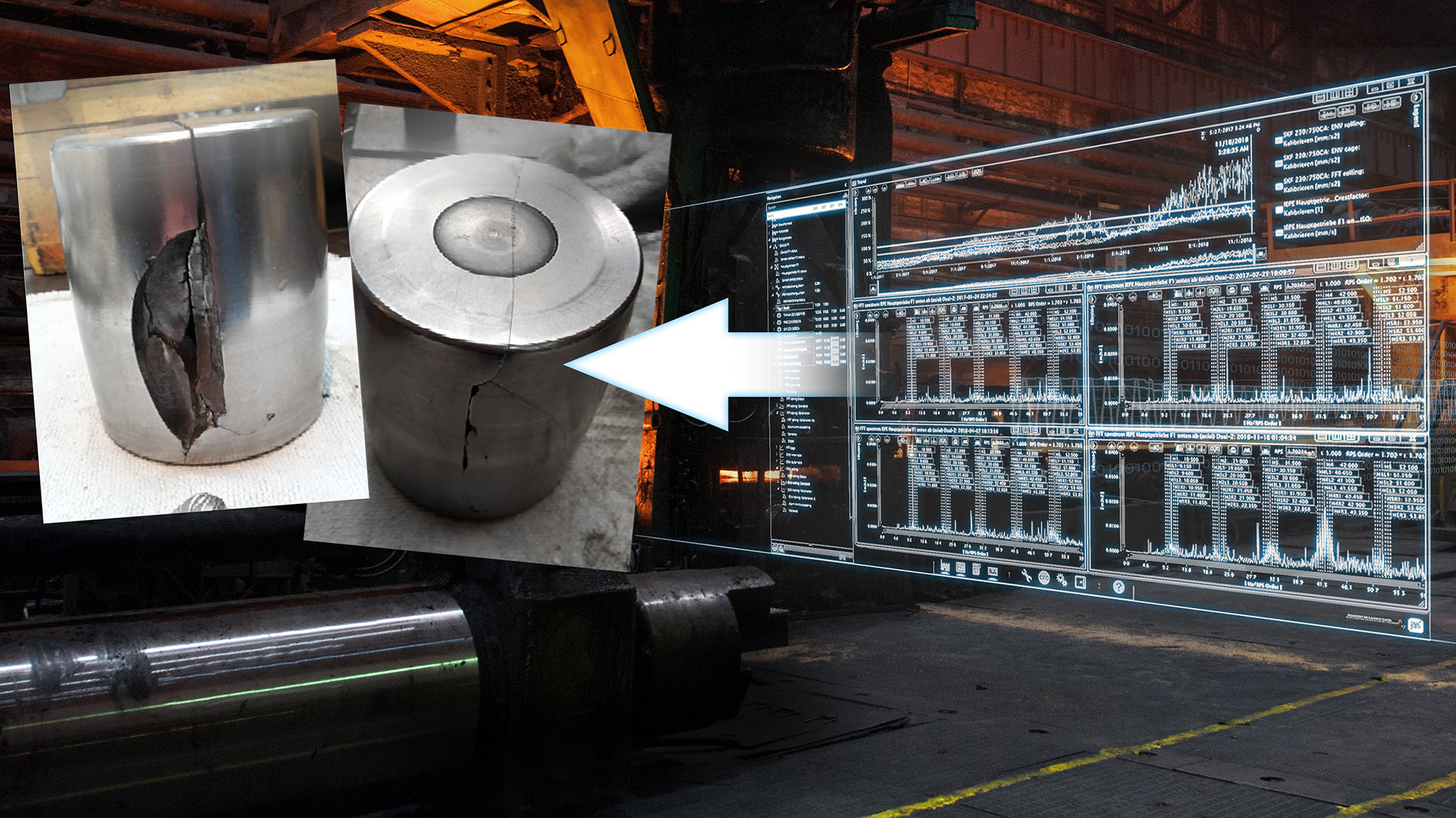

The production line is divided into several sections (measuring locations), where the quality relevant data are acquired. At first, the measuring data are recorded separately based on the measuring locations, together with the material ID and the position (length) of the strip in relation to the measuring location.

This creates as many measurement files as measurement locations. When the product (coil) is finished (e.g. defined by shear cut) the measurement data are extracted from the temporary single files based on the material ID and the length positions and will be written into a new file – the QDR data file. All measurement values belonging to the recently produced strip are stored scaled to the final product length. Production- related material elongations are taken into account.

Product Features

Easy Configuration and wide Range of Interfaces

ibaQDR is based completely on ibaPDA and the iba hardware. Therefore the whole iba connectivity is available. The signals to be measured are configured in the same I/O Manager as in ibaPDA.

Online Status Display

The status of the recording is monitored continuously in a special window showing the current material-ID and length at the measuring location, no matter whether a recording is running or not.

Configuration of the Measuring Location

Besides the name of a measuring location further information is entered in the configuration dialog, such as control signals from material tracking, like material- ID and actual length position.

Scalable System Size

An appropriate number of measuring locations can be defined throughout the line. Another arbitrary number of measuring signals can be assigned to each measuring location.

Analyzing with Standard Tools

The data files which are generated by ibaQDR can be analyzed and displayed with ibaAnalyzer. Demanding reports can be generated with the powerful report generator.

Quality Data Management

Using the software ibaAnalyzer-DB the recorded data can be provided to higher level systems, such as MES (Manufacturing Execution System), DataWarehouse or individual applications in a plain and transparent database structure.

This software is one of many useful add-ons of ibaPDA

作为 iba 系统的核心部分,ibaPDA 证明了自身是多年以来用于维护和生产的最为通用的数据采集系统之一。客户端-服务器架构、灵活记录、凭借自动检测轻松配置众多令人信服的功能之一。

Success Stories

请联系 当地经销商。

Please note: As ibaQDR works in close relation to the segment mapping of the automation, a detailed knowledge of the functioning of the automation is required for the configuration.

Therefore we recommend the integration of the system through a qualified supplier or together with support services (consulting, training, support).