ibaInCycle

Online monitoring of cyclical processes for quality assurance and machine diagnosis

ibaInCycle monitors cyclically recurring and rotating processes online. A precise forecast of quality features is therefore possible already during production. Implementing measures promptly can prevent damage and malfunctions of machines or plants, thereby ensuring the product quality.

ibaInCycle at a Glance

- Online monitoring and analysis of cyclical processes (recurring process steps, rotating mechanics)

- Identifying process anomalies

- Automatic alarming in real time

- Saving raw data for detailed analysis in measurement files

- Outputting characteristic values for the long term analysis in higher- level systems

- Online visualization of measured data and characteristic values

- Self-learning module for different process conditions (auto-adapting)

- Reference curves for various process conditions

- Individual definition of warning and alarm limits

- Comprehensive configuration options

Application examples

ibaInCycle is ideal for a number of applications, such as:

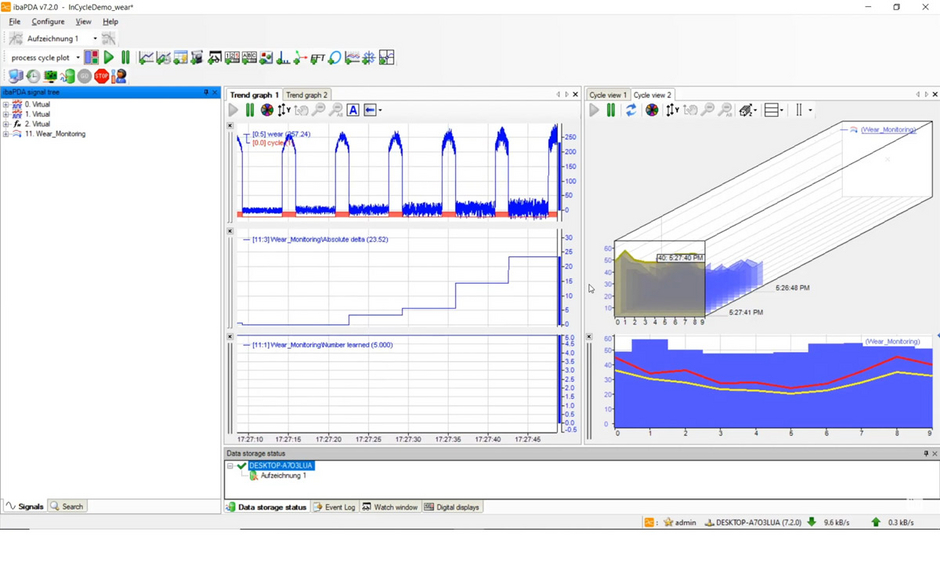

- Monitoring saw blade wear

- Monitoring sequential processes in plants and on machines

- Monitoring step responses and roll stand characteristics

- Motor and gear monitoring

- Robot/handling systems, especially for monitoring traverse movements (load and/or reference runs)

- Monitoring recurring production steps, such as

- presses (force, displacement and pressure curves)

- injection molding

- crane monitoring ...

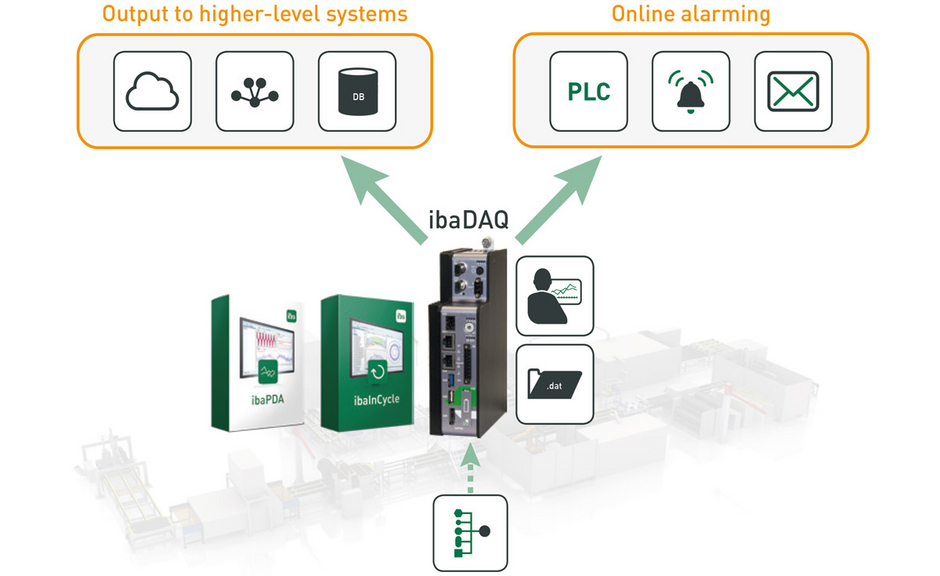

Compact standalone solution

It is not only possible to operate ibaInCycle on a central system, but also on the edge device ibaM-DAQ. This compact monitoring solution can be used right on the machine on site as a standalone solution.

ibaM-DAQ is a processor module of the modular measurement system ibaMAQS. Via the Ethernet interfaces, process data can be recorded directly at the machine. With the interface module ibaM-FO-2IO, further iba devices can be connected via fiber optics.

Automatically learn process sequence

The Auto-Adapting module is capable of learning the ideal process sequence from a number of curves. In the learning phase, a reference curve is learned for this purpose, which also takes different process conditions into consideration, such as different material properties, geometries, temperatures, speeds, etc.

Product Features

Identifying early-stage process changes and anomalies

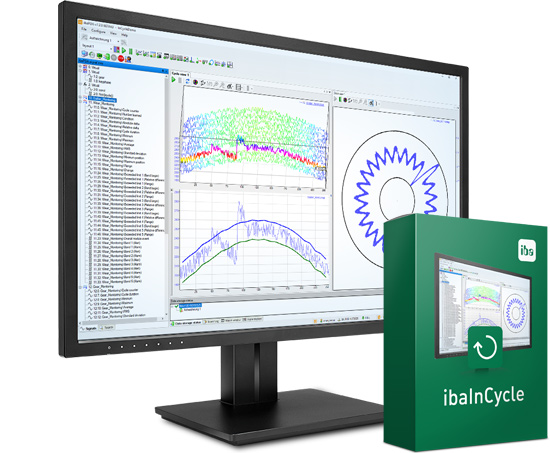

ibaInCycle is an add-on to ibaPDA and monitors all types of cyclically repeating processes, such as recurring processes, but also rotating machine parts, i.e. rollers, gears, etc.

Compact standalone solution

It is not only possible to operate ibaInCycle on a central system, but also on the edge device ibaDAQ. This compact monitoring solution can be used right on the machine on site as a standalone solution.

Functionality of ibaInCycle

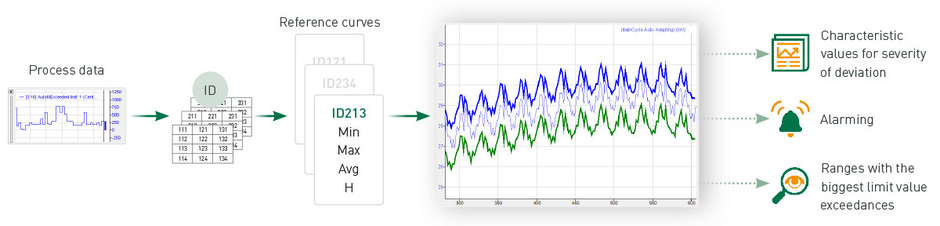

Process signals from cyclical processes ideally exhibit similar behavior within a cycle. ibaInCycle compares the “learned” good process with the actual process signal and calculates meaningful characteristic values.

Meaningful characteristic values

The InCycle Expert module makes it possible to divide process cycles evenly into any number of ranges and freely define meaningful characteristic values for any range.

Alarming in real time

The characteristic values of any area are monitored for changes. For processes consisting of several steps, the cycles can be divided into several sub-cycles.

Output to higher-level systems

The characteristic values can be output to higher-level systems, such as databases and cloud systems, for a long term analysis. The measurement files with the raw data can be used for detailed analyses.

Demonstrative visualization

The cycle view, which was developed specifically for ibaInCycle, offers several demonstrative types of visualization. In the waterfall view, cycle changes over time are displayed particularly clearly.

Automatically learn process sequence

The Auto-Adapting module is capable of learning the ideal process sequence from a number of curves. In the learning phase, a reference curve is learned for this purpose, which also takes different process conditions into consideration, such as different material properties, geometries, temperatures, speeds, etc.

Automatic monitoring and alarming

In the monitoring phase, the Auto-Adapting module compares the reference curve with the measured curve. In the process, permitted deviations can be individually defined using warning and alarm limits.

ibaInCycle

Tutorials

How to monitor Outlier with the Auto Adapting Module

In this video we will show you what the new Module “InCycle Auto Adapting” can be used for.

How to detect Wear with the Auto Adapting Module

In this video we will show you how to detect Wear with the ibaInCycle Auto Adapting Module.

How to detect Gear Teeth Failure with the Expert Module

In this video we will show you how to monitor a rotating gear in mesh having a damage on one of its gear teeth using our InCycle Expert Module.

This software is one of many useful add-ons of ibaPDA

Центральным компонентом системы iba является ibaPDA, за многие годы использования она зарекомендовала себя одной из самых многофункциональных систем для сбора измеренных данных для производства и техобслуживания. Архитектура клиент-сервер, гибкая запись данных и простое конфигурирование с функцией автораспознавания - это только малая часть преимуществ baPDA.

Свяжитесь с Вашим локальным торговым представителем.

| Order no. | Name | Description |

|---|---|---|

| 30.670040 | ibaQPanel-V7-Add-On | Add-On license for ibaPDA for to display process and quality data on an HMI window |