Detecting critical vibrations in rolling mills

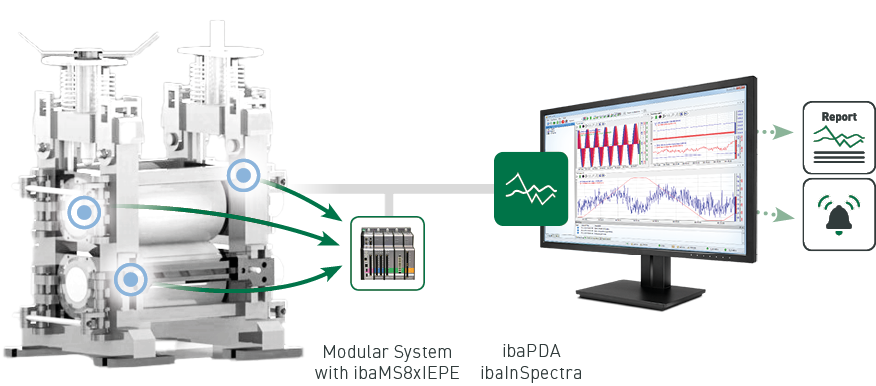

In rolling mills, many vibrations may occur that have negative effects on the life cycle and the state of the plant, but also on product quality. If wear and defects are detected early enough, appropriate counter-measures can be initiated for reducing waste and downtimes. Anyway, the user has to know exactly the vibration behavior of the plant and set it into relation to other process data from the plant. In a cold rolling mill, the process data recording system ibaPDA has been used for process data analysis, but the vibration measurement data was evaluated separately. With ibaInSpectra as add-on to the ibaPDA system, the acquired vibration signals can be analyzed within defined frequency ranges. Simultaneously, processes with all machine, material and quality data can be monitored.

Business Benefits

Automatic alarm

in real time when limit values are exceeded

Easy integration

in the existing iba system

Minimizing false alarms

by taking process parameters into consideration

The Technology

Cold rolling mills show a complex vibration behavior, consisting of natural vibrations of the plant mechanics as well as excitations from the drive or bearings but also vibrations caused by defects. The aim of the monitoring is to detect vibrations that are caused by external excitation or faults. In this particular case, acceleration sensors on the chocks which serve as bearing for the rolls give insight into the vibration behavior of the whole stand. During normal operation, the natural vibrations of the stand are in the low-frequency range. High-frequency vibrations are an indicator for external excitation. With ibaInSpectra, these vibrations can be assigned to individual components.

Günter Spreitzhofer

Application & Consulting,

iba AG

iba Products